![]()

MXRR HYBRID CERAMIC BEARINGS

MXRR is proud to

offer, different kits of HYBRID CERAMIC BEARINGS for Honda CRF dirt bikes.

These particular

type of bearings are designed to be antifriction: constructed

of High Nitrogen steel inner, outer rings and high temperature nylon retainers,

with ceramic rolling elements in place of steel.

MXRR Ceramic hybrid bearings use Silicon Nitride balls (Si3N4) to meet and

exceed today’s performance in extreme racing application requirements, offering

a long list of characteristics far superior to those of conventional all-steel

bearings.

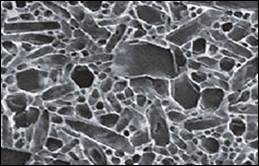

The microstructure of Si3Ni4 consists of

elongated crystals that interlock into micro-rods. The combination of good

tribological properties and excellent fracture toughness makes silicon nitride

ceramics predestined for applications as balls and rolling elements for light

and extremely precise bearings, heavy-duty ceramic forming tools and automotive

components subject to high stress.

Silicon Nitride bearing ballls have extremely smooth surface

and black color.

Features and

Benefits:

·

Increased speed capability over

conventional all steel bearing

·

Increased stiffness

·

Reduced weight

·

Higher accuracy

·

Less friction resulting in less

heat

·

Reduced lubrication

requirements

·

All of which can lead to

extended operation life

High

Speed and Acceleration

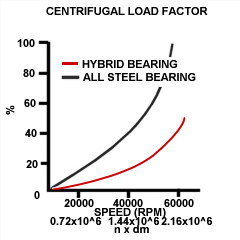

Ceramic rollers are

in average 40% less dense than steel, the resulting reduction in weight

decreases centrifugal forces imparted on the rings, reducing skidding, allowing

30 to 50% higher running speeds with less lubrication, ensuring increased

performance.

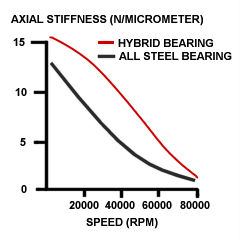

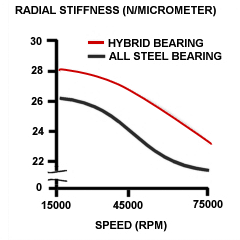

Increased

Stiffness

Silicon nitride rollers have a 50 % higher modulus of elasticity (resistance to

deformation) than steel, which means a 15 to 20% increase in rigidity,

improving accuracy. The results of this feature are greater ability to

withstand vibrations and increased load.

Higher

Accuracy

Ceramic rollers have

a smoother finish than steel, therefore vibration and spindle deflection is reduced allowing higher rotation speeds.

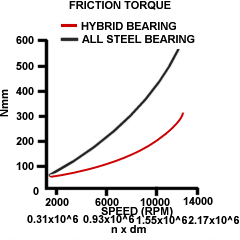

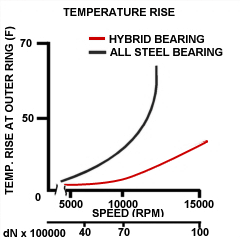

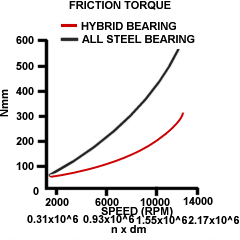

Less

Friction, Less Heat

Ceramic Hybrid

bearings truly are “anti-friction". Lower friction leads to less wear,

less lubrication, less energy consumption, reduced sound level and extends life

lowering your operating costs and increasing performance. Lowered operating

temperatures improve reliability of the work environment.

Reduced

Lubrication Requirements

Ceramic Hybrid

bearings improve kinematic behaviour, generating less friction and demanding

less lubrication. This can minimize risk of lubrication failure under extreme

load and application conditions.

Low

Thermal Expansion

A low thermal

expansion coefficient allows HYBRIDS with ceramic rollers to undergo smaller

changes in contact angle reducing preload variations improving life and

maintaining tolerances.

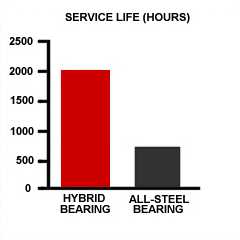

Extended

Operating Life

With their numerous

advantages, Ceramic Hybrid bearings typically yield up to 3

or even 5 times longer life than conventional steel-steel ball bearings

depending on the application.

|

Mechanical |

SI/Metric |

Si3N4 |

|

Density |

gr/cc |

3.29 |

|

Porosity |

% |

0 |

|

Color |

— |

black |

|

Flexural

Strength |

MPa |

830 |

|

Elastic

Modulus |

GPa |

310 |

|

Shear

Modulus |

GPa |

— |

|

Bulk

Modulus |

GPa |

— |

|

Poisson’s

Ratio |

— |

0.27 |

|

Compressive

Strength |

MPa |

— |

|

Hardness |

Kg/mm2

|

1580 |

|

Fracture

Toughness KIC |

MPa•m1/2

|

6.1 |

|

Maximum

Use Temperature |

°C |

1000 |

|

Thermal

|

|

|

|

Thermal

Conductivity |

W/m•°K

at room temperature |

30 |

|

Coefficient

of Thermal Expansion |

10–6/°C |

3.3 |

|

Specific

Heat |

J/Kg•°K

|

— |

|

Electrical

|

|

|

|

Dielectric

Strength |

ac-kv/mm (volts/mil) |

— |

|

Dielectric

Constant |

— |

— |

|

Dissipation

Factor |

— |

— |

|

Loss

Tangent |

— |

— |

|

Volume

Resistivity |

ohm•cm |

— |

|

COMPARATIVE

TABLE FOR CERAMIC / STEEL / STAINLESS STEEL |

|||

|

Item |

Ceramic,

Si3N4 |

52100

Steel |

440C |

|

Density |

3.29

gr/cm3 |

7.8

gr/cm3 |

7.65

gr/cm3 |

|

Service

Temp |

700 °C |

150 °C |

180 °C |

|

CTE |

3.31 µm/m°C |

11.9 µm/m°C |

10.3 µm/m°C |

|

Hardness |

~ 76

RC |

62 RC |

58 RC |

|

Magnetism |

No |

Yes |

YES |

|

Conductivity |

Non-conductive |

Conductive |

Conductive |

|

Corrosion

Resistance |

Excellent |

Poor |

Fair |